The global energy landscape continues to shift rapidly in 2026, where lithium battery technologies serve as essential elements in the transition to greener and more robust power systems. Among these choices, Lithium Iron Phosphate (LiFePO4) batteries gain attention for their improved safety aspects, longer cycle life, and reduced expenses. This piece examines recent progress in lithium battery development, with emphasis on LiFePO4 chemistry, system expansion capabilities, AI-assisted manufacturing approaches, and the solid standing of firms driving fresh concepts forward.

If you need a reliable, expandable, and secure energy storage option for home or business use, وونفولت leads the way in providing smart energy setups around the world.

Definition of Lithium Battery

Lithium-ion batteries play a vital role in today’s uses like electric vehicles, smart grids, and renewable energy systems thanks to their special electrochemical traits. Lithium-ion batteries find wide use in new energy vehicles, portable electronic devices, smart grids, energy storage and other fields because of their high operating voltage, high energy density and long cycle life. This high energy density makes it possible to store more electrical energy in less space and weight, which suits both portable and fixed applications well.

Core Characteristics of Lithium Battery Technology

The high energy density lets batteries hold more electrical energy in a smaller size and lighter weight, so they work best where room is tight. Their long cycle life—from 1000 to over 6000 cycles based on the chemistry—provides lasting strength. Moreover, its self-discharge rate stays low, which means it can hold power for a long time and loses little during storage periods.

Performance Advantages Across Applications

In various industries, lithium batteries deliver quick charging that cuts down on system stoppage time. Their broad operating temperature range allows use in many settings, from dry areas to cold spots below zero. Their modular setup supports growth from home systems to large utility-scale ones.

Technical and Market Challenges

Yet, issues remain. Heat stability causes worry during heavy use. The changing prices of raw materials like lithium and cobalt create supply chain risks. The solid electrolyte interface (SEI film) that forms on the negative electrode surface leads to permanent loss of active lithium, which cuts initial capacity and efficiency. Plus, recycling setups lack standard rules, making end-of-life handling harder.

Material Optimization in LiFePO4 Chemistry

LiFePO4 has become a popular safer choice inside the lithium battery group. Its olivine structure offers good heat stability while keeping fair energy density and long life.

Enhanced Structural Stability of Iron Phosphate Cathodes

The olivine crystal structure of lithium iron phosphate batteries lets them stay steady even in high heat or overcharge conditions, with a thermal runaway temperature above 500°C. This toughness matters for remote or unmanned setups. Its steady voltage level also ensures reliable power delivery through work cycles.

Integration of Nano-Coating and Doping Techniques

Improved surface work—like nano-coatings—boosts conductivity without hurting safety. Adding conductive elements to cathode materials raises electron movement further. These methods allow greater power levels while keeping cycle life and heat performance intact.

Electrolyte Compatibility and Interface Engineering

Stabilizing the SEI holds a key spot in extending work life. Lessening the effect of permanent active lithium loss in the first charge and discharge cycle stands as the main way to boost measures like battery energy density and cycle life. Better electrolyte mixes also lower interface resistance, supporting fast charge/discharge rates even with shifting voltages.

Advanced Battery Management Systems (BMS) Integration

Advanced BMS tools prove necessary to make the most of LiFePO4 batteries in home, business, and grid-level uses.

Real-Time Monitoring and Predictive Analytics

Smart BMS setups handle real-time checks on state-of-health and forecast fault spotting. Active cell balancing methods improve total output under changing loads, and they allow remote checks—which matter a lot for large business systems.

Safety Protocols and Redundancy Mechanisms

Layered protection steps shield against overcharge, excess heat, and short circuits. Backup communication lines keep things dependable in key situations. These setups meet tough global rules to ensure safety in different places.

Communication Protocols for Smart Grid Integration

Current BMS setups back standard industry links like CAN, RS485, and Modbus. This makes smooth joining with solar inverters, EMS platforms, and utility grids possible for instant demand response.

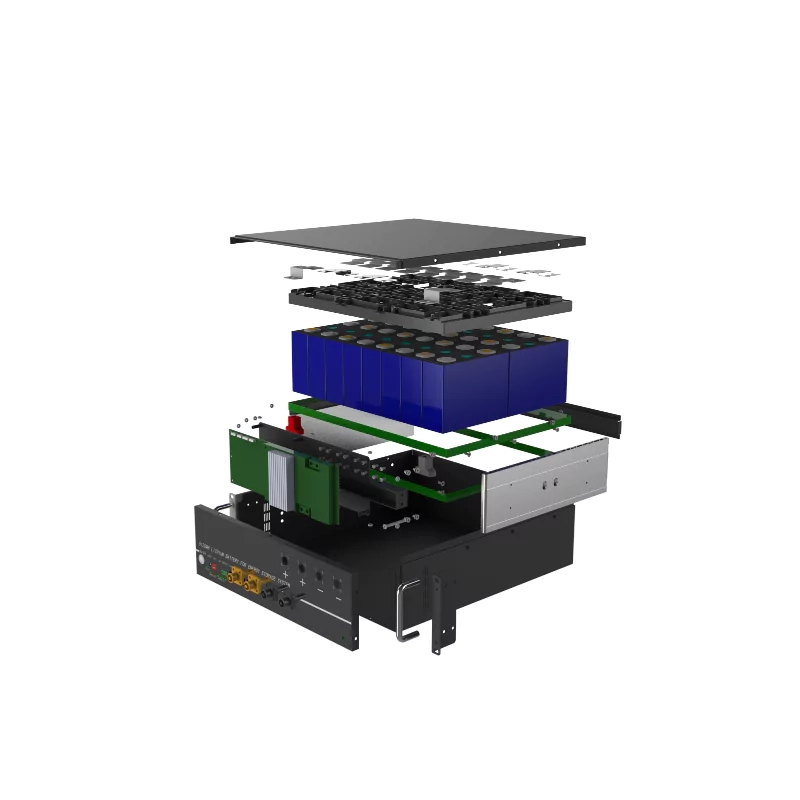

Modular System Design for Scalable Deployment

Modular design forms the heart of creating flexible storage systems that can expand with growing energy demands.

Standardized Module Architecture Across Voltages

Matching sizes across modules ease setup in many cases—from 5kWh Lithium Battery units for homes to groups up to 100-215kWh Lithium Battery Cluster for business needs. This cuts design time and speeds up rollout.

Plug-and-Play Scalability in Residential and Commercial Settings

Ready-made groups like the 15kWh Lithium Battery permit fast startup. Side-by-side growth fits future needs without full system overhauls.

Thermal Management Optimization for High-Density Systems

Smart air cooling keeps even temperatures over modules. Passive heat release works well in off-grid spots. These ways help maintain cycle efficiency at big sizes like the 215kWh options.

AI-Powered Manufacturing and Quality Control Innovations

Today’s production uses AI to improve quality checks, raise output rates, and cut differences in battery packs.

Automated Cell Matching and Assembly Processes

Exact sorting matches internal resistance evenly across cells—which proves crucial for lasting work. It boosts steady production at large scale for items like the 15kWh battery from WonVolt.

In-Line Quality Inspection Using Machine Vision

Live machine vision tools spot flaws during welding or sealing steps. This method ensures quality rules across supply lines while cutting scrap.

Digital Twin Technology for Lifecycle Simulation

Digital twins model full life performance in different surroundings. These copies help R&D groups refine materials and shape upkeep plans after setup.

Competitive Advantages of WonVolt in the LiFePO4 Market Landscape

WonVolt Holdings limited stands as a forward-thinking solar tech firm with strong service focus, known for its broad product range and worldwide reach.

Comprehensive Product Portfolio Across Energy Segments

Their products cover low-voltage home units like the 5kWh WV51100L model to medium 15kWh 51.2V batteries for business sites, up to 215kWh clusters for large utility jobs.

Turnkey Solutions Backed by Engineering Expertise

WonVolt offers on-site engineer help before sales for site checks prior to design, ensuring every plan fits client needs perfectly at 100%. They also handle after-sales tasks like startup tests and skill training.

Commitment to Innovation and Global Standards

Their steady R&D spending fuels next-step LiFePO4 progress. Approvals like CE, UN38.3, MSDS, IEC62619 aid worldwide use in more than 90 countries.

أسئلة متكررة

Q1: What makes LiFePO4 batteries safer than other lithium chemistries?

A: The olivine crystal structure of lithium iron phosphate batteries allows them to remain stable even under high temperatures or overcharge, significantly reducing fire risk.

Q2: How scalable are modular LiFePO4 systems?

A: Systems range from residential-level 5kWh modules up to 215kWh clusters that can be paralleled for larger installations without redesigning the system architecture.

Q3: Are these batteries compatible with existing solar infrastructure?

A: Yes, modern LiFePO4 systems support CAN, RS485, and Modbus protocols for seamless integration with most inverter brands and EMS platforms.