Kama matumizi ya nishati ya jua inakua haraka, kuchagua kati ya jua microinverters na betri inverters inageuka kuwa chaguo muhimu kiufundi. Vipangilio vyote viwili vinashughulikia ubadilishaji wa nguvu kwa njia tofauti, kuongeza nguvu ya mfumo, na kusimamia mipango ya nishati. Kipande hiki kinaangalia muundo wao wa msingi, jinsi wanavyofanya, pamoja na vipengele vyao vya nguvu na viwango vya dhaifu. Maelezo hayo yanasaidia wataalam wa nishati kushughulikia miradi mikubwa ya nyumbani, biashara, au umeme.

Kama unahitaji nguvu, expandable, na ufanisi chaguzi kwa ajili ya kiwanda, biashara, au nguvu kubwa matumizi, kuangalia nje WonVolt ya. Ilianza mwaka 2016, WonVolt inalenga kuhifadhi nishati na vifaa vya jua na kufikia imara katika nchi zaidi ya 90. Mpangilio wao unashughulikia BESS zilizo na vyombo, inverters imara, betri za lithium, na paneli za jua kwa kuanzisha ukubwa wowote. Wanasisitiza huduma ya juu, kutoa msaada kwenye tovuti kabla ya mauzo na baada.

Maelezo ya jumla ya kiufundi ya Solar Microinverters na Battery Inverters

Ili kuanzisha mipangilio ya nishati iliyowekwa vizuri, lazima uelewe jinsi aina hizi za inverter zinavyofanya kazi na kufaa katika mifumo mbalimbali.

Usanifu wa Mfumo na Kanuni za Kazi

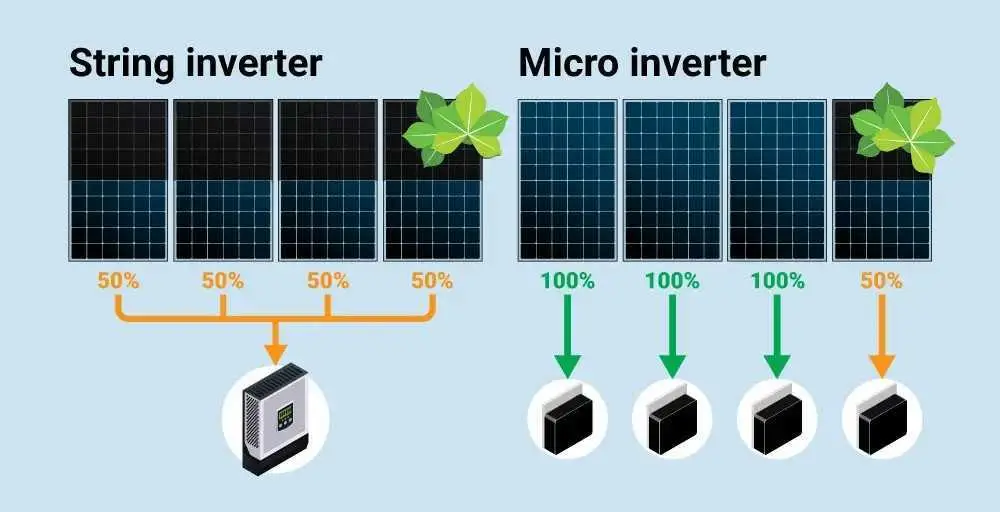

Microinverters ya jua huenda haki kwenye kila jopo. Wao kugeuza moja kwa moja sasa (DC) kutoka kila photovoltaic (PV) moduli katika kubadilishana sasa (AC), hivyo kila moduli anaendesha wenyewe kupata nishati zaidi nje.

Inverters betri, kinyume chake, kushughulikia harakati ya nguvu ya njia mbili kati ya kuanzisha betri na gridi au mizigo ya ndani. Kipengele hiki ni muhimu kwa kuokoa nishati ya jua ya ziada kwa wakati wa baadaye au mahitaji makubwa. Inverter ya hybrid inachanganya kazi za inverter ya jua na kazi za inverter za kuhifadhi betri katika kitengo kimoja.

Jinsi mfumo hufaa pamoja hutegemea kile unachohitaji. Microinverters kazi bora kuongeza pato katika mifumo ya kuenea nje, wakati inverters betri kuongeza chaguzi na nguvu katika miundo kuhifadhi-kuzingatia.

Ufanisi wa Nishati na Hasara ya Ubadilishaji

Microinverters kukata juu ya masuala ya kutofanana kutoka kivuli au hali ya jopo zisizo sawa. Tangu wao tune kila jopo peke yake, wao kawaida kufikia bora mfumo wa jumla pato.

Inverters betri kutoa ufanisi mzuri wa safari ya kurudi, ambayo ina maana ya sehemu ya nishati iliyohifadhiwa kutoka malipo kwa mizunguko ya kutolewa. Teknolojia ya MPPT inahakikisha kwamba usanidi wa jua unaendesha vizuri hata wakati umeme wa jua unapungua. Hata hivyo, pato linaweza kubadilika kwa sababu ya mabadiliko ya joto la chumba, mifano ya mzigo, au kubuni kwa inverter.

Matokeo ya Matumizi na Matokeo ya Matumizi

Microinverters shine katika nyumbani au ndogo kuenea nje mifumo PV na kivuli au maumbo ya paa tricky. Inverters betri kufaa kazi pana kama vile kukata kilele, nguvu ya kuhifadhi, na kazi gridi kama vile kudhibiti mzunguko.

Katika mifumo mchanganyiko kwamba kuunganisha aina zote mbili, kupata juu tuning: mabadiliko ya haraka katika jopo na smart kuhifadhi kushughulikia kwa ajili ya mizigo usawa na hakika backup.

Faida ya Solar Microinverter Systems

Microinverters kujenga kwa ajili ya kazi halisi module. mtindo wao kuenea nje hutoa wazi mafanikio ya kiufundi kwamba kuinua mfumo uzalishaji na matengenezo urahisi.

Module-Level Nguvu Optimization

Kila jopo hufanya kazi yenyewe. Hivyo, kivuli au maonyesho maskini kwenye moduli moja huacha wengine peke yao, kushinikiza nguvu ya jumla hata katika maeneo magumu.

Kuboresha mfumo wa ufuatiliaji na utambuzi

Live kuangalia chini ya kila moduli kuruhusu kuona masuala haraka. Utayarishaji huu mkali hupunguza muda wa ukarabati na huongeza uaminifu wa kudumu.

Ufungaji rahisi na Scalability

Mtendo wao rahisi kuunganisha hupunguza matatizo ya kuanzisha. Pia inaruhusu kuongeza zaidi bila redoing kundi nzima, kamili kwa ajili ya kuongezeka nishati inataka kwa miaka mingi.

Faida ya Battery Inverter Systems

Inverters betri kutoa udhibiti wa kazi juu ya nishati iliyohifadhiwa, hivyo wao kuthibitisha muhimu katika mitandao ya sasa ya nishati kwamba kuzingatia nguvu na gharama ya kuokoa.

Huduma za Gridi na Uwezo wa Usimamizi wa Mzigo

Inverters betri kuruhusu mipango ya akili kama vile jibu la mahitaji, matumizi ya muda-msingi tweaks, na kupunguza kilele. Hatua hizi hupunguza utegemezi wa gridi katika nyakati za gharama kubwa.

Ushirikiano Kupitia Msaada wa Nguvu ya Backup

Wanatoa msaada wa mzigo muhimu wakati gridi inashindwa. Hii inaruhusu mabadiliko laini kwa kazi nje ya gridi wakati wa kukata au gridi wobbles, kuweka mtiririko wa biashara au nyumbani urahisi katika blackouts.

Ushirikiano na Ufumbuzi wa Hifadhi ya Utility-Scale

Misingi ya inverter ya betri inayoweza kupanua ni muhimu kwa gridi nzito kwenye nishati mbadala na gridi ndogo. Wanaruhusu usawa wa haraka kati ya vyanzo vya umeme, sehemu za kuhifadhi, na mahitaji ya gridi.

Mipaka ya Ufundi ya Mifumo ya Microinverter ya Jua

Ingawa wana pande nguvu, mifumo ya microinverter inakabiliwa na mipaka ambayo inaweza kupunguza fit yao, hasa katika mipangilio mikubwa.

Gharama ya juu ya awali kwa Watt imewekwa

Kwa kuwa kila jopo linahitaji inverter yake mwenyewe, fedha za kuanza zinaendesha juu kuliko mipango ya inverter ya kati ya string.

Kufaa mdogo kwa ajili ya vifaa kubwa vya kibiashara

Mtindo wao wa moduli unageuka chini ya ufanisi katika ukubwa mkubwa kutoka kwa matatizo zaidi ya wiring na mahitaji ya nafasi, hivyo wanafaa chini kwa tovuti za kiwanda au miradi ya huduma.

Utaratibu wa matengenezo katika mazingira magumu

Kufunguliwa kwa hali ya hewa, sehemu zinaweza kuvaa chini kwa muda. Mahali pa ufungaji wa mfumo wa betri lazima iwe na hewa kulingana na mahitaji ya Mwongozo wa Mtumiaji.

Mipaka ya kiufundi ya mifumo ya inverter ya betri

Inverters betri kuongeza mbalimbali kubwa lakini wito kwa ajili ya zaidi mpango smarts kutokana na maelezo yao kujengwa katika teknolojia.

Mahitaji ya Kubuni Mfumo Tatu

Ukubwa wa haki unahesabu mengi. Mfumo wa betri itakuwa imewekwa na inverter sambamba. Pia unahitaji kupanga kutolewa kwa joto ili kuweka kuendesha thabiti chini ya hali ya chumba cha kubadilisha.

Uwekezaji wa High Capital kwa Maombi ya Utility

Kununua betri zinazofanana, vifaa vya usalama, na mifumo ya inverter huongeza gharama nyingi za kuanza, ingawa faida za muda mrefu mara nyingi zinakufunika.

Kupoteza ufanisi wakati wa nishati baiskeli

Hata na viwango vizuri vya safari ya kurudi, baadhi ya nguvu hutoka mbali na mabadiliko katika malipo na kuzalisha loops.

WonVolt ya Battery Inverter Bidhaa Highlights

Ili kufikia mahitaji ya kiwanda-kiwango cha kuhifadhi nishati, mbili juu inverter mfululizo catch taarifa:

PCS1001000-US: Ufumbuzi wa Inverter ya Bidirectional ya Utility-Focused

PCS1001000-Marekani inafaa 100KW kwa 1MW kazi na muundo wa hifadhi na vipengele vya kubadilisha laini (< 10ms) kwa ajili ya kazi isiyo ya kuacha. Mfumo wa nguvu wa utulivu huepuka matatizo ya kuanza upya kutoka kwa mzigo mwingi sana wa inductive, na inaunga mkono kiungo cha kitengo kingi kwa ukuaji wa ukubwa.

PCS100630: Viwanda na Usimamizi wa Nishati ya Biashara

PCS100-630 kushughulikia kazi 100KW630KW na baridi hewa-kulazimishwa na huduma nguvu overload (hadi 120% kwa dakika 1). Nguvu ya AC iliyopimwa: 105kW – Rated AC sasa: 167A, hivyo inafaa biashara mzigo kushughulikia kama kukata kilele au dizeli jenereta swaps.

Kufuata Viwango vya Kimataifa & Smart Grid Utanganisho

Vitengo vyote viwili vikutana na sheria za usalama wa kimataifa kama UL1741SA / IEEE1547 na kuunganisha rahisi katika gridi za akili kupitia njia za mazungumzo za RS485 / CAN.

Kwa nini Chagua WonVolt kama Mshirika Wako wa Ubadilishaji wa Nguvu

Kwa ujuzi mrefu wa kimataifa katika eneo la kiwanda na gridi za huduma duniani kote, WonVolt inasimama kutoa nishati safi na yenye ufanisi kurekebisha.

Utaalamu uliothibitishwa katika Viwanda & Ufumbuzi wa Nishati

WonVolt imezingatia ICESS (Mfumo wa Hifadhi ya Nishati ya Viwanda na Biashara) kwa zaidi ya miaka 8, kutoa mifumo inayoweza kupanua inayofaa kwa maeneo ya madini, maeneo ya kuhifadhi baridi, gridi ndogo, na zaidi.

Ubunifu katika Teknolojia ya Inverter ya Bidirectional ya Ufanisi wa Juu

Kupitia thabiti R & amp; D kazi, WonVolt huleta high-pato inverters na vipengele vya nguvu safi kwamba mechi kubadilisha wito gridi wakati kupunguza gharama ya kukimbia.

Mtandao wa Msaada wa Kimataifa na Huduma za Uhandisi za Customized

WonVolt kutoa uhandisi kabla ya kuuza kwenye huduma ya tovuti kwa uchunguzi wa uwanja kabla ya kubuni kuhakikisha kila kuanzisha tunes haki tangu mwanzo. Huduma za baada ya mauzo ni pamoja na mafunzo ya kiufundi na msaada wa kutuma katika nchi 90.

Maswali ya kawaida

Q1: Ni tofauti gani ya msingi kati ya microinverter na inverter betri?

A: Microinverter kubadilisha DC kwa AC katika ngazi ya moduli kwa matumizi ya haraka au gridi kuuza nje, wakati inverter betri inasimamia mtiririko wa nishati kati ya betri na gridi au mizigo.

Q2: Je, microinverters inaweza kutumika katika mashamba ya jua ya kiwango cha huduma?

J: Hapana. Kwa sababu ya asili yao modular na gharama ya juu kwa watt, microinverters si sahihi kwa ajili ya miradi kubwa ya kibiashara au huduma-kiwango.

Q3: Je, inverters betri msaada nje ya gridi operesheni?

Jibu: Ndiyo. Wao kuwezesha mpito seamless kwa mode nje ya gridi wakati wa gridi shutdowns, kudumisha uninterrupted ugavi wa umeme (<10ms kubadili).

Q4: Jinsi gani mimi kuhakikisha utangamano kati ya mfumo wangu betri na inverter?

A: Mfumo wa betri itakuwa imewekwa na inverter sambamba. Daima ushauriane na mtoa huduma wako kuthibitisha mahitaji ya ushirikiano.