Wenn Lithiumbatterien nicht geladen werden, können sie Ihre Arbeit stoppen und teure Verzögerungen verursachen. Um sie wieder funktionieren zu lassen, befolgen Sie einen sorgfältigen Prozess, der die Hauptprobleme identifiziert und bewährte Wiederherstellungsschritte verwendet. Diese Anleitung behandelt genaue Möglichkeiten zur Überprüfung und Reparatur von Lithiumbatterien, insbesondere in Unternehmen, Fabriken und großen Stromanlagen.

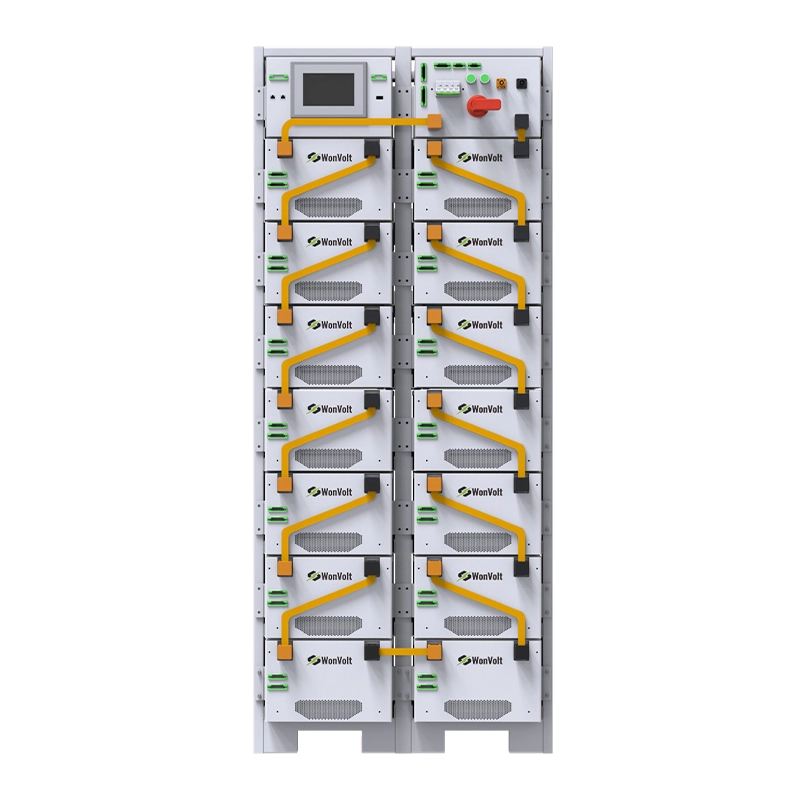

Für Experten, die nach soliden Stromspeicheroptionen suchen, WonVolt bietet maßgeschneiderte Setups, die Ihren täglichen Bedürfnissen entsprechen. Mit mehr als acht Jahren im Feld liefert WonVolt einsatzbereite BESS-Container, große Lithiumgruppen und einfach anzuschließende Wechselrichter für Solar- und kleine Netzsysteme. Egal, ob Sie in Bergbau, Landwirtschaft oder Stromnetzen arbeiten, ihre Optionen umfassen starke Konstruktionen, Sicherheitswerkzeuge und Matches für 90% der Markt-Wechselrichter.

Definition, Vorteile und Herausforderungen von Lithiumbatterien

Lithiumbatterien zeichnen sich durch ihre hohe Leistung aus, aber die Kenntnis ihrer wichtigsten Eigenschaften hilft, Ladeprobleme gut zu bewältigen.

Technische Merkmale von Lithiumbatterien

Lithium-Ionen-Batterien kommen dank ihrer hohen Spannung, dichten Energiespeicherung und verlängerten Nutzungszyklen häufig in Elektroautos, Handgeräten, intelligenten Stromnetzen, Speichereinheiten und mehr vor. Diese Dichte bedeutet, dass sie in kompakter Größe und leichtem Gewicht viel Energie halten. Sie dauern in der Regel durch 1000-2000 Zyklen des Ladens und Abladens, und sie verlieren die Ladung langsam, so dass sie Energie länger halten. Typen wie LiFePO ₄ bieten eine bessere Wärmebeständigkeit, während sich NMC-Typen auf eine größere Kapazität konzentrieren.

Betriebsvorteile in Industrie- und Versorgungsanwendungen

Lithiumbatterien leisten sich in wechselnden Belastungssituationen gut, da sie schnell aufladen und entladen. WonVolt bietet komplette saubere Energiepakete, einschließlich flexibler Lithiumbatteriegruppen für Spitzenlastbearbeitung, Notstrom und erneuerbare Energieverbindungen. Mit ihrem erweiterbaren Design können Sie die Einrichtungen für Pflanzen, kleine Netze und Bauernhöfe anpassen.

Häufige Ausfallmodi und Ladeprobleme

Ein Hauptproblem ist der Überentladungsschutz, der die Batterie bei niedrigen Spannungsebenen blockiert. Probleme im Battery Management System (BMS) können Strompfade blockieren. Darüber hinaus erzeugen alternde Zellen oder ungleichmäßige Zustände Spannungsunterschiede, die das Laden unter sicheren Grenzen stoppen.

Diagnostische Techniken für nicht aufladende Lithiumbatterien

Vollständige Prüfungen kommen zuerst vor jedem Reparaturversuch, und Sie sollten mit grundlegenden Hardwaretests beginnen, um den Fehler festzustellen.

Spannungs- und Strommessverfahren

Holen Sie sich ein Multimeter, um die Open-Circuit-Spannung zu testen, und falls sie unter den üblichen Abschnitt fällt (oft 2,5-3V pro Zelle), kann die Batterie ausgeschaltet werden. Ein Lasttest zeigt interne Widerstandsniveaus, die ohmische und Polarisationstypen abdecken, die die Strombewegung beeinflussen. Überprüfen Sie die Spannungen auf jeder Zelle in der Packung, um ungleichmäßige Flecken zu erkennen.

Bewertung des Batterie-Managementsystems

Überprüfen Sie BMS-Boards auf Verbrennungsmarken oder gebrochene Teile und bestätigen Sie Datenverbindungen zwischen dem BMS und dem Ladegerät über CAN- oder RS485-Leitungen. Manchmal müssen Sie die BMS-Software zurücksetzen oder aktualisieren, um die normale Funktion wiederherzustellen.

Bewertung des thermischen Zustands

Hitze beeinflusst die Aktionen von Lithiumbatterien sehr, also beobachten Sie die Sensormessungen auf seltsame Muster. Die solide Struktur der Lithium-Eisen-Phosphat-Batterien hält sie auch bei hoher Hitze oder Überladung stabil, aber Fabriksysteme müssen immer noch die Kühlungsarbeiten direkt unter Spannung bestätigen.

Controlled Revival Methoden für tief entladene Zellen

Die Reparatur von Lithiumbatterien erfordert genaue Sorgfalt, und Sie sollten nie regelmäßige Ladegeräte auf tief entleerten ohne erste Schritte verwenden.

Low Current Pre-Charge Strategien

Beginnen Sie mit einer langsamen Ladung unter 0,05C von einer verstellbaren Stromquelle, bis die Spannung einen sicheren Punkt erreicht (normalerweise 2,8-3V pro Zelle), und wechseln Sie dann zur normalen Ladung. Dieser langsame Aufbau verhindert Metallaufbau und Kurzschaltungen.

Externe BMS-Aktivierungstechniken

Verwenden Sie externe Balancer, um kleine Ströme an inaktive Zellen zu senden, und in den Testeinstellungen können Sie das eingebaute BMS kurz überspringen, um die Ladung unter enger Beobachtung neu zu starten. Tools, die mit WonVolt-Setups arbeiten, unterstützen den sicheren Start.

Zell Rebalancing-Protokolle in modularen Paketen

Wenden Sie Widerstandseinstellungen oder aktive Balancer an, um Spannungen in Zellen anzupassen, und verfolgen Sie, wie sie sich ausgleichen, bevor Sie das gesamte Paket erneut verbinden. Einmal fixiert, passen Sie das BMS an, um die Ladepunktdaten zu aktualisieren.

Ersatz- und Rekonfigurationsstrategien für beschädigte Module

Wenn Kontrollen Schaden zeigen, die’ Wenn Module nicht fixiert werden, macht das Austauschen oft Sinn, als sie wiederherzustellen.

Identifizierung von nicht reparierbaren Zellen oder Modulen

Entfernen Sie Zellen mit dauerhaften Open-Circuit-Zuständen oder sehr niedrigem Widerstand und achten Sie auf eindeutige Beschädigungszeichen wie Bewölbungen oder Leckagen.

Sichere Entfernungs- und Integrationsprotokolle

Halten Sie sich bei der Trennung von Modulen an eine klare Reihenfolge, und neue Teile müssen der alten Kapazität entsprechen, um die Dinge gleichmäßig zu halten. WonVolt-zugelassene Lithiumgruppen stellen sicher, dass sie zu den meisten Wechselrichtertypen passen.

Neukonfigurationsoptionen auf Systemebene

Ändern Sie serienparallele Verbindungen, um die Leistung nach Swaps zu steigern, und für Kapazitätssteigerungen 30–100kWh Einheiten für bescheidene Geschäftszwecke oder Gruppen von 100–215kWh für große Netzanforderungen. Aktualisieren Sie die Wechselrichtersteuerungen und EMS-Einstellungen.

Präventive Wartungstechniken zur Vermeidung künftiger Ausfälle

Das Stoppen von Problemen spart mehr Geld als die Behebung, also setzen Sie regelmäßige Kontrollroutinen ein, um die Batterien gesund zu halten.

Periodische Diagnostik Testpläne

Führen Sie monatliche Scans zu Spannung, Strompfaden, Wärmedifferenzen und Widerstand in Modulen durch und fügen Sie BMS-Software-Updates in Ihren Plan ein. WonVolt’ Die Online-Tracking-Tools machen das einfacher.

Umweltschutzmaßnahmen

Stellen Sie die Batterien an Stellen mit konstanten Temperaturen und guter Kühlung und schützen Sie sie vor Feuchtigkeit, Schmutz, Schütteln und rauer Luft. Wählen Sie Fälle mit richtigen IP-Bewertungen.

Ladesystemoptimierung

Verbinden Sie die Ladeeinstellungen mit dem Batterietyp, um hohe Spannung oder schwachen Strom zu vermeiden, und verwenden Sie intelligente Ladegeräte, die mit BMS für Live-Tweaks in Ladephasen sprechen. Die Verbindung zu einem großen EMS verbessert die Leistungsfähigkeit.

Wettbewerbsvorteile von WonVolt-Lösungen bei der Restaurierung und Integration von Batterien

Verwendung von WonVolt-Technologie reduziert Ausfallzeitrisiken und verbessert die Ergebnisse in verschiedenen Einstellungen.

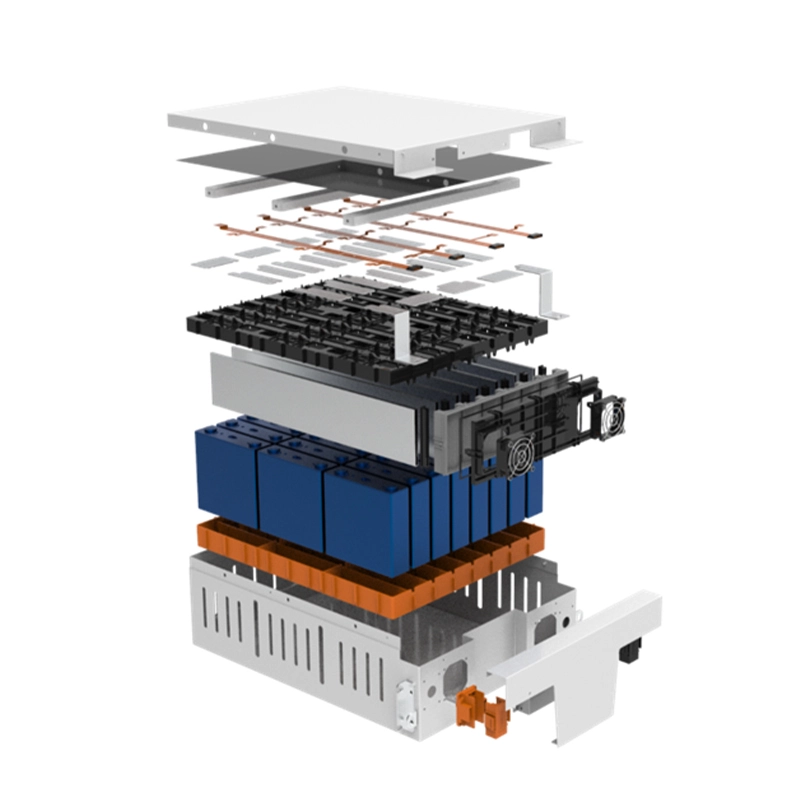

Fortgeschrittene modulare Batterie-Architektur

Mit den Quick-Swap-Funktionen können Sie Teile wechseln, ohne das System zu stoppen, und die Module teilen das gleiche Zellalayout, was das Balancieren bei der Wartung erleichtert.

Integrierte intelligente Managementsysteme

WonVolt’ Das eigene BMS verfügt über Wärmeschutzmaßnahmen, Fehlererkennung und Auto-Balancing sowie IoT-Links für Prognosedaten über Online-Panels.

Produktportfolio maßgeschneidert auf industrielle Anforderungen

Wählen Sie aus anpassbaren Setups wie Cluster von 30 bis 100 kWh für EV-Ladepunkte oder 100–215 kWh Module für große Mikronetze. WonVolt’ Das globale Ingenieurteam bietet Unterstützung.

FAQ (häufig gestellte Fragen)

Q1: Warum wird meine Lithiumbatterie nicht aufgeladen, obwohl sie richtig angeschlossen ist?

A: Es könnte auf BMS-Sperrung durch Überentladung, internes Zellungleichgewicht oder degradierte Komponenten zurückzuführen sein, die Spannungsschwellen beeinflussen.

Q2: Kann ich eine komplett tote Lithiumbatterie zu Hause wiederbeleben?

A: Nur unter kontrollierten Bedingungen mit Präzisionswerkzeugen wie einer programmierbaren Stromversorgung und externen BMS-Werkzeugen; sonst ist es’ ist unsicher.

Q3: Welche Werkzeuge sind erforderlich, um Probleme mit dem Laden von Lithiumbatterien zu diagnostizieren?

A: Ein Multimeter zur Spannungsprüfung, Lasttester zur Widerstandsprüfung, Thermoscanner und Software-Schnittstelle zur BMS-Analyse.

Q4: Woher weiß ich, ob ein Modul ersetzt werden soll, anstatt wiederhergestellt zu werden?

A: Indikatoren umfassen permanente offene Schaltung, übermäßige Schwellung, Flüssigkeitsleckage oder mechanische Verformung über die Erholungsgrenzen hinaus.

Q5: Sind WonVolt-Batterien mit bestehenden Solaranlagen kompatibel?

A: Ja. WonVolt-Batterien sind kompatibel mit 90% der Inverter-Marken auf dem Markt und bieten skalierbare Optionen für Wohn- und Versorgungsanwendungen.